TE100

190HP

Power

13.5km/h

Working speed

40km/h

Traveling speed

3200L

Grain tank capacity

- Product comparison

Features

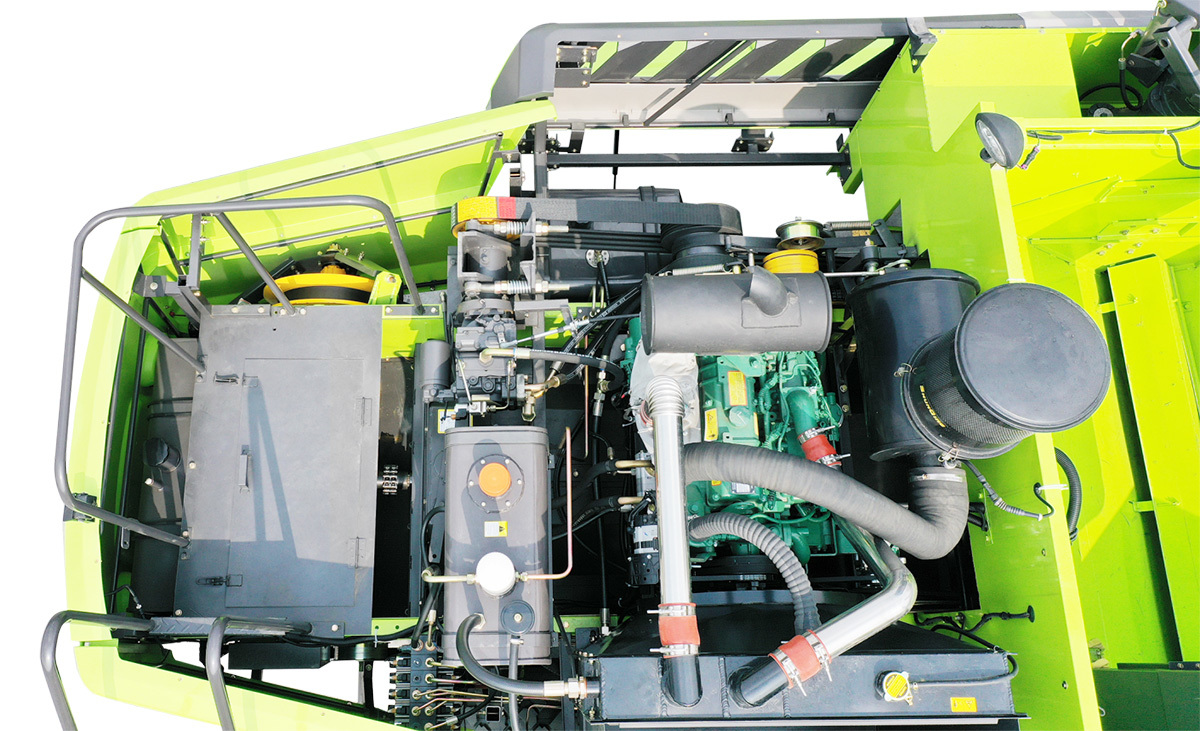

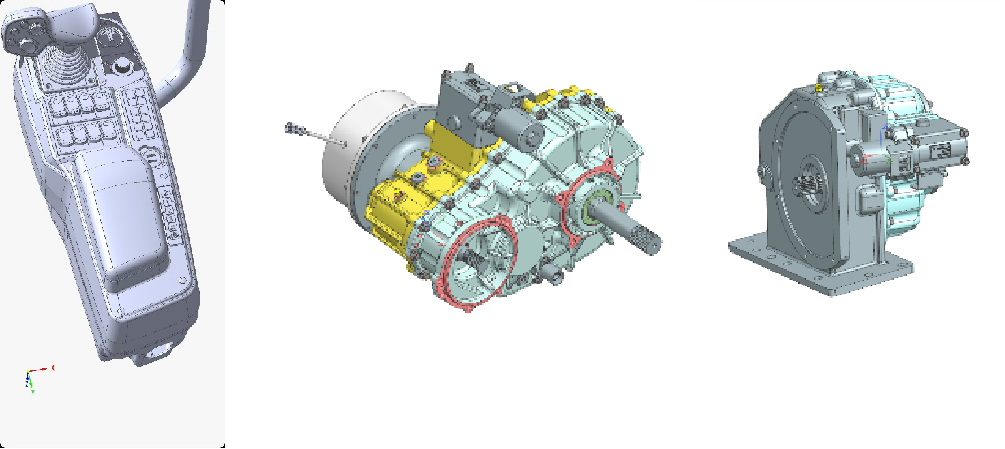

Powertrain

The dual fuel tank design has a fuel tank capacity of up to 400L, which can meet the needs of a whole day's operation, and the effective operation time is longer and the benefits are better.

Cyclone tube air prefilter, low maintenance frequency and easy maintenance.

Yuchai 190 horsepower, four-cylinder high-pressure common rail engine,National III emission, torque reserve of 19%,low fuel consumption, reliable performance.

In high-latitude areas, where cold and low temperatures are likely to occur during grain harvesting operations, an oil circuit preheating system can be installed to provide more protection for the engine and avoid early wear.

Innovative use of plate-fin radiator and open radiator cover, with high heat transfer coefficient and thermal conductivity, large heat dissipation area, and good cooling effect, avoiding high temperature.

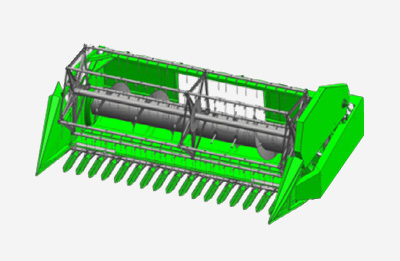

Harvesting and feeding system - conveyor

|

|

|

|

The bridge is 1246mm long and 920mm wide. Large feeding volume, easy and smooth

● Four-row telescopic tooth lever with good crop grasping effect. Assembly design for quick replacement according to different operation requirements.

● Original three-row tooth conveyor chain rake, with high grasping force, stable grasping and good durability.

● PEER maintenance-free bearings (no need to add lubricating oil in the cavity) are used for the drive and driven shafts of conveyor, with high durability and a service time of 600-800 hours.

● The tension of the conveyor chain rake can be adjusted by tension screw, for crops compaction and smoother and evener feeding.

● The sealing plate material and optimized structure ensure that the rubber always fits tightly during the movement of the shaking board.

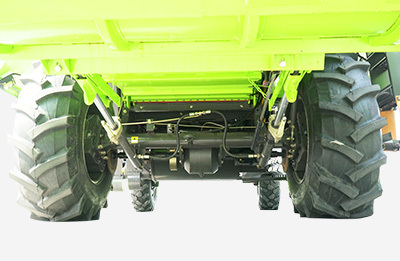

Travel system

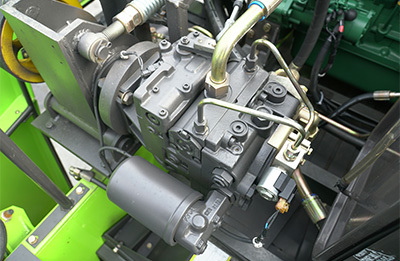

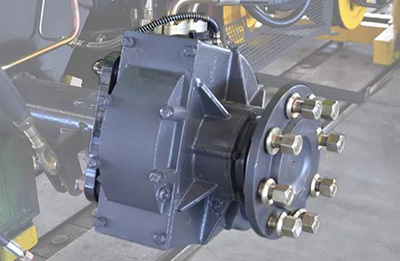

Hydrostatic drive, with efficient and reliable power transmission

● Adopts hydrostatic drive chassis, front wheel drive and hydraulic power assisted rear wheel steering, with a max. travel speed of up to 30 km/h.

● The rear wheel allows a turning angle of 45°, and the frame structure is optimized, with a turning radius of 6 m, for easy turn on the ground.

Hydraulic power assisted rear wheel steering allows a turning angle of 34° |

75cc variable displacement pump,with good travel stability. |

Hydrostatic drive chassis, with comfort and less effort in operation. |

The optimized wheel reducer system is external mesh type three-axis transmission, with high reliability and adaptability. |

Threshing and cleaning system

Efficient threshing and excellent cleaning

|

|

|

|

The main threshing technology composed of "stepless adjustment of drum speed + concave plate spacing + T-shaped drum cover with diversionable flow" is suitable for grain threshing with different threshing difficulties.

The main threshing drum is φ620×3180mm Tooth shank threshing to meet the needs of a variety of crop threshing The main threshing drum driven by the hydraulic motor has infinitely adjustable speed.

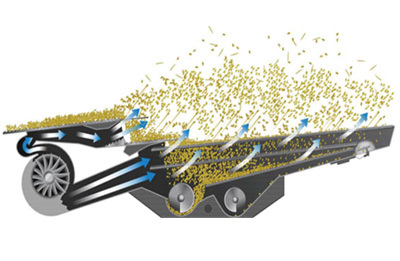

Three-stage, double-layer, adjustable cleaning technology

The cleaning system adopts an independent jitter plate double-layer co-directional vibrating screen, which is more convenient for the adjustment of different crops; The width of the cleaning screen reaches 1m, and the area reaches 2.4m³. The wind speed of the main fan is adjustable at 8~15m/s, and the well-designed air duct can make the grain and straw mixture fluffy, separate and discharged under the action of wind.

Secondary complex detachment structure

The secondary threshing and reprocessing of the grain branches and stems with unclean threshing and more excess were carried out to reduce the loss of grain and improve the cleanliness of screening.

Straw grinder

By increasing the diameter of the driving wheel, the speed of the crushing blade is increased, and the inlet blade is added at the front of the chassis to make the straw crushing better. Adjustable grass discharge board is dispatched, so that the range and uniformity of straw throwing can be adjusted. The length of the broken straw is 5-8cm, and the maximum throwing width can reach 3 meters.

Grain bin and unloading systems

● Lifted up to 4500mm

● Horizontal traversing height

● 3200mm The rotation angle is 90°

Large capacity grain bin · Equipped with a 3200L large-capacity grain silo to reduce the number of grain discharge, it can ensure long-term uninterrupted continuous harvesting operations. |

Fast unloading · Widened plate vertical lifting + horizontal auger unloading, optimizing the auger meshing mode, improving the speed and applicability of grain discharge; · The unloading cylinder is thickened to 350mm, and the whole grain can be completed in 2.5 minutes |

Suitable for different needs · Adjustable top unloading device, standard unloading height of 4.5m, for high unloading can meet the demand; · The vehicle is equipped with a 1m long unloading cylinder rubber, which is suitable for high-level truck unloading and manual bagging. |

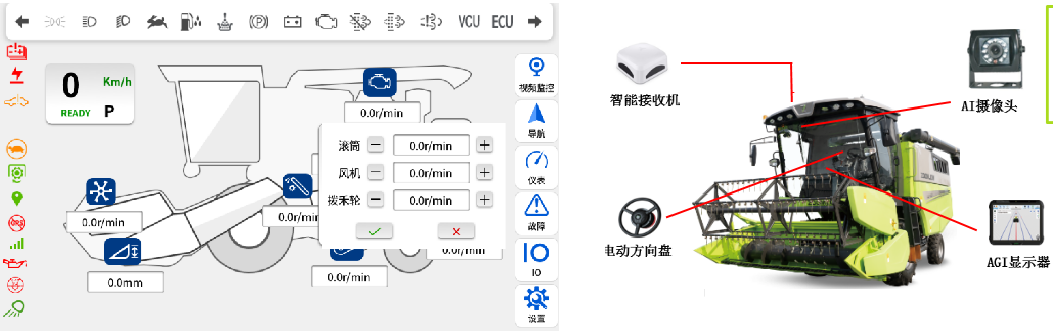

Cabin

New advanced intelligent cab, 30% more spacious, providing the comfort, convenience and intelligent features required by the operator.

The 180° view of horizon on almost every side and adequate illumination for night work;

Integrated display, providing the working state of the machine, motor speed, etc.; fault diagnosis and warning functions, for easy fault diagnosis and maintenance, and minimum loss.

The console has a reasonable layout, whose frequently used operation keys are arranged in a convenient place by fully combining with the driver's operation habits, so as to improve the harvesting operation convenience.

The travel and action elements are controlled by an electro-hydraulic handle, which is easier to learn than a lever-type operating system. You can master all its operations with only a simple training of half an hour.

The control buttons of several hydraulic actuators are integrated in a CAN panel, which makes the operation simpler and more direct that you can turn on/off various functions with one button.

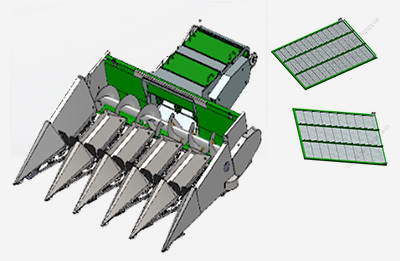

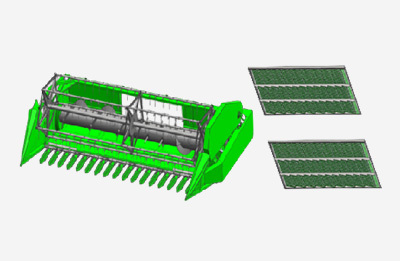

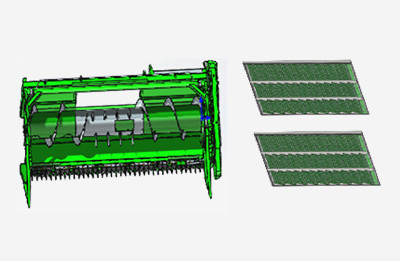

Replace the header, one machine for multiple purposes

The TE series wheeled grain combine harvester is fully compatible with different demands of various crops in cutting, threshing and cleaning from the beginning of design, thus retaining the greatest variability and combinability.

Sorghum harvesting: Add header accessories7*410 |

Corn harvesting: Replace corn header, upper and lower 6*560\5*560\5*650\5*700\5*750\4*900 punching screens |

Millet harvesting: Add header accessories, concave plate 7*410 accessories and cleaning screens |

Soybean harvesting: Add header accessories, concave plate accessories and cleaning screens |

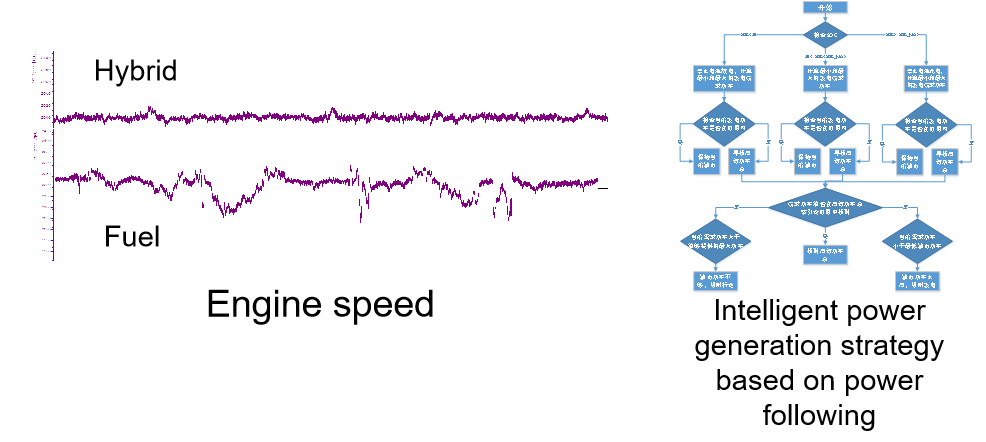

Hybrid Model

TE100-DH Hybrid Combine Harvester

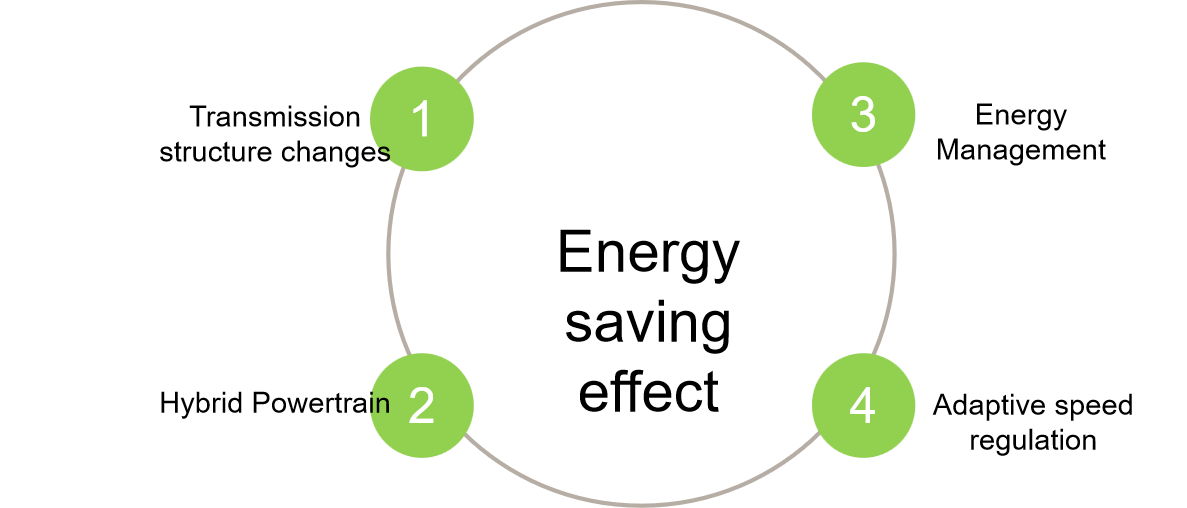

Based on TE100PRO as the prototype, independent motor direct drive is implemented for some reels, threshing drums, travel and fans, which simplifies the transmission mechanism, improves the reliability of the whole machine and reduces energy consumption.

Hybrid Model

|

Multi-motor coordinated control 1. Efficient |

|

|

Hybrid energy-saving technology 2. economic Comprehensive fuel saving of more than 25% |

|

|

Hybrid energy-saving technology 2. intelligent |

|

Product Parameters

Dimensions & Technical parameters

|

Model |

TE100 |

|

Overall dimensions (L*W*H) |

7200×3280×3420mm |

|

Overall weight |

7100kg |

|

Engine rated power |

147kW |

|

Engine rated speed |

2200r/min |

|

Emission |

China III, high-pressure common rail |

|

Fuel tank volume |

400L |

|

Working width (wheat header) |

2750/2960/3250/4000mm |

|

Min. ground clearance |

330mm |

|

Working speed |

1.6~13km/h |

|

Productivity per pure working hour |

0.8~1.6hm2/h |

|

Fuel consumption per unit area |

≤35kg/hm |

|

Threshing drums quantity |

1Pcs |

|

Threshing drums type |

Single longitudinal axial flow |

|

Threshing drums Outer diameter * L |

φ620*3180mm |

|

Fan type |

Centrifugal |

|

Fan diameter |

φ450mm |

|

Fan quantity |

1Pcs |

|

Concave sieve |

Grid |

|

Cleaning screen |

Air elutriator |

|

Grain collection box volume |

2000L |

|

Unloading mode |

Mechanical unloading |

|

Drive type |

Mechanical |

|

Max. ground clearance of unloading outlet |

Max. 4.3 m (lifted by lateral movement) |

|

Straw chopper type(optional) |

Cutting device |

|

Straw chopper working width |

800mm |

|

Cab type |

A/C cab |

|

Gearshift method |

Mechanical Variable Transmission + |

|

Drive axle (front axle) type |

Hydrostatic drive |

|

Drive type |

Two-wheeldrive(frontwheeldrive, rear wheelsteering) |

|

Rear axle |

Rear axle is not adjustable |

|

Steering engine type |

Hydraulic |

|

Brake type |

Clamp brake |

|

Wheel base |

2788mm |

|

Guide wheel (rear wheel) |

1810mm |

|

Drive wheel (front wheel) |

1900mm |

|

Guide wheel |

300/80R15.3;12.5/80R15.3 |

|

Drive wheel |

540/70R24;15-24 |

|

Wheel reducer type |

Closed |

|

A/C |

Cold air |

|

Corn header |

Five-row 750mm corn header (optional) |

|

Soybean header |

Optional |

|

Special header for sorghum |

Optional |

|

IoT terminal |

Optional |

Images

Video

VR View

Key words:

Service

Ask for a quote

Thank you for your attention to Zhonglian. If you have any cooperation needs for products or services, please contact us in time. After receiving your consultation information,

The service consultant of Zhonglian will understand your purchase needs in detail within 24 hours and provide you with the lowest product quotation.

ZOOMLOINFull-process mechanization solutions

ZOOMLOINFull-process mechanization solutions ZOOMLOINProducts VR

ZOOMLOINProducts VR Global

Global